Long-term operation of PV systems

Direct investment in a photovoltaic system delivers on its promises – if you actively take care of it. What exactly should you be doing as an operator of a PV system? Learn the keys to successful operational management.

The return and value retention of your direct investment strongly depend on the operational management. Complete and timely filing of all documents is absolutely fundamental to being prepared for critical situations during the operating period (over at least 20 years).

Sufficient time and money must be invested in the ongoing operation, lest yield losses occur. For example, system performance will suffer if dirty modules are not cleaned. Neglected maintenance can cause costly downtime and unnecessary increases to repair costs.

Here, you’ll learn the keys to making your operation successful and receive an overview for deciding which tasks you want to take into your own hands and which you’d rather delegate to external service providers.

Ensure value retention

Value retention can be damaged by a faulty installation or defective system parts. In such cases, however, you may be able to make a legal claim. Guarantee claims may exist against the installation company in the event of faulty installation: depending on the circumstances, you can demand supplementary performance or replacement. The purchase agreement may include warranty rights against the seller for defective or faulty system parts. The seller’s guarantees may also have been contractually agreed.

In order to make legal claims, it is important to have all documents available.

Complete documentation

Well-kept documentation of the photovoltaic system is crucial for all commercial and organisational tasks – regardless of whether it is an existing or new system. It comes into play for:

- Maintenance/repair

- Sale and handover of the plant

- Disputes with service providers, installers, or manufacturers

- Guarantee and insurance claims

- Legal disputes

System documentation checklist

The EU standard DIN EN 62446 (German version IEC 62446:2009) serves as a guideline for the complete documentation of a photovoltaic system. It defines standard procedure for documentation and bundles all relevant system data for customers, operators, and inspectors. This includes:

- Contracts, such as purchase, works, insurance and service provider contracts, other documents necessary for ongoing operation

- Address data, such as system location, including contact person, operator contact details, responsible grid operator, contact details of the operations manager if available

- Relevant economic data, such as commissioning date, feed-in commitment, EEG remuneration rate, feed-in concept data, and documents such as permits, registration with the Federal Network Agency, registration in the core energy market data register

- Relevant technical data, such as data sheets for the PV modules and inverters, circuit diagram, terminal plan, site plan, general plan, substructure structural analysis

- Guarantees, such as the terms of guarantee from the PV module manufacturer and the inverter manufacturer

Legally required retention periods

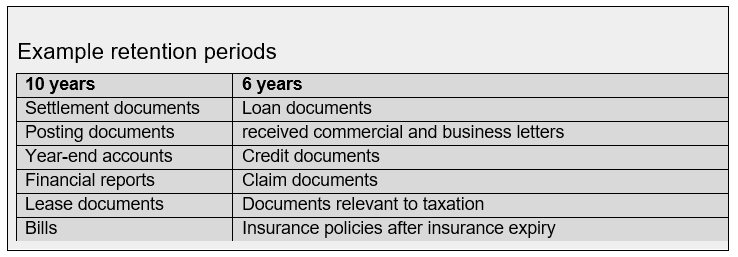

The length of time for which documents must be retained is stipulated by law. Some documents must be kept for at least 6 to 10 years according to § 257 HGB (Handelsgesetzbuch, the German Commercial Code) and § 147 AO (Abgabenordung, the Fiscal Code of Germany).

Others for shorter periods due to special legal standards, e.g. 5 years according to § 15 BBodSchutzG (Bundes-Bodenschutzgesetz, the Federal Soil Protection Act), or 3 years according to § 42 KrW/AbfG (Kreislaufwirtschafts- und Abfallgesetz, the Closed Substance Cycle Waste Management Act). As a rule, contracts must be retained for as long as rights and obligations arise from them.

System management

Nowadays, specialised service providers offer their expertise in all areas. The cost-benefit ratio is an important factor when deciding which services to commission from third parties. You should take your own working time (opportunity costs) into account, as well as the fees of any service providers.

Whether or not third-party services are profitable depends on the pricing model and the services agreed upon.

Commercial management

The commercial tasks of operations management include finance (financial accounting, preparation of year-end accounts, liquidity management, financial controlling), contract and risk management (deadline monitoring, contract optimisation, claims handling), and management (communication with partners, service providers, and banks).

Which tasks you delegate and which you carry out yourself depends on your available time and familiarity with the subject matter. Year-end accounts, however, may only be prepared by tax advisors. All other commercial tasks are not legally bound to a professional qualification. However, each commercial task brings its own challenges:

- Yield forecast validation: In cases of existing systems that have been taken over, the actual age-related power losses must be clarified in order to calculate with realistic yield forecasts.

- Financial accounting: Legal requirements must be fulfilled, although these are continuously changing.

- Reporting obligations and tax regulations: All requirements pertaining to the chosen legal form must be fulfilled.

- Financial controlling: Optimisation and saving opportunities must be identified.

- Contract management: You can reduce ongoing costs by keeping an eye on services and conditions, as well as by altering contracts or any potential service providers.

- Financial planning: Planning must be complete and encompass all expected operating costs, for the benefit of insurance or clarification. In addition, adequate reserves should be maintained so that repair costs in the event of damage can be easily taken care of. The best possible basis for calculating these reserves is a realistic assessment of the technical system condition.

- Preparing for the end of remuneration: A successive power marketing system should be organised well before the system drops out of the EEG tariff after 20 years.

Annual obligation to report to the Federal Network Agency

As an electricity producer/own supplier, you must notify the Federal Network Agency of the previous year’s electricity yield by 28 February each year – you may otherwise be subject to sanctions

Technical management

Direct investment only works if returns can be secured, risks minimised, and values maintained. Technical management works towards these goals via permanent remote monitoring of the yield data, regular maintenance including the obligatory DGUV (Deutsche Gesetzliche Unfallversicherung, German Social Accident Insurance) inspections, incident management (diagnosis, damage settlement), and system maintenance (module cleaning, grounds maintenance to prevent shade).

In order to maintain system performance and value, you will also require controlling using meaningful key figures. It must be clear whether the system’s technical performance is already satisfactory or if there is still room for improvement.

Depending on how much time is available and the level of expertise that is required, you can commission service providers for individual tasks, such as maintenance, or for the full scope of technical management work.

However, structural analysis and work on electrical installations in the public grid may only be carried out by structural engineers or electricians. Technical management presents several challenges requiring firm technical knowledge:

- Rapid fault resolution: In the event of a malfunction, quick reactions are vital to preventing major yield losses. It is advantageous here if you or your service partners are local on site and able to quickly remedy the problems.

- Maintenance and inspections: Technical problems on site must not only be reliably detected, but maintenance must also be carried out in a timely fashion to meet legal requirements.

- Yield data monitoring: By continuously comparing target values with actual values, slowly creeping yield reductions should be detected as early as possible so that the causes can be found and eliminated in time. For this purpose, the comparative values of similar systems should be used.

- Risk-minimised work: The technical operation itself should not be the cause of any damage. For example, module cleaning must not cause microcracks. Likewise, appropriate cleaning equipment should be used in order to preserve warranty claims.

This article was written with the support of Nadja Steuer, Legal Counsel, and Guido Fiebes, Managing Director, at the equity investment society aeos energy Gesellschaft für Kapitalbeteiligungen mbH.

This article was published in our investment guide. For all other articles and information on Direct investment in commercial-sized photovoltaic systems, please visit: Milk the Sun – PV Investment Guide.